I am in my final semester of a Robotics Engineering Bachelor's degree (expected December 2023)

from Michigan Technological University. My primary interests are in automotive, robotics, and software.

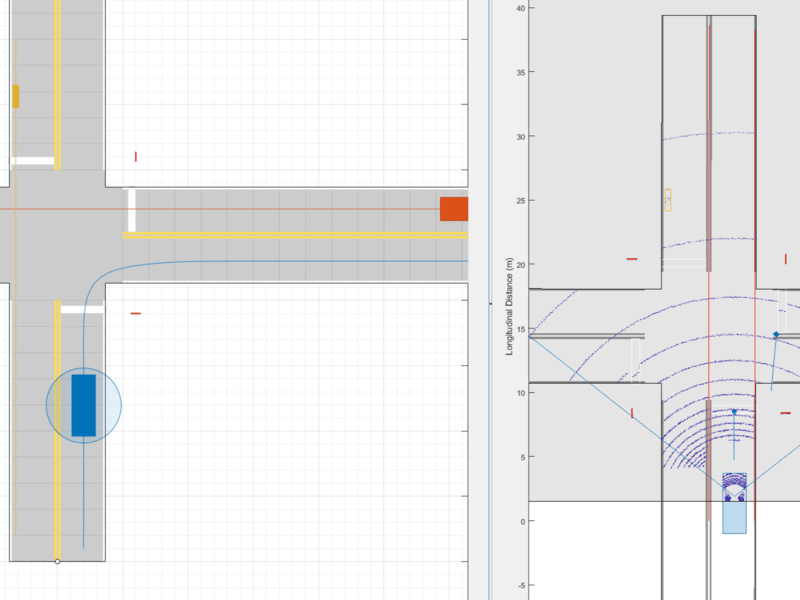

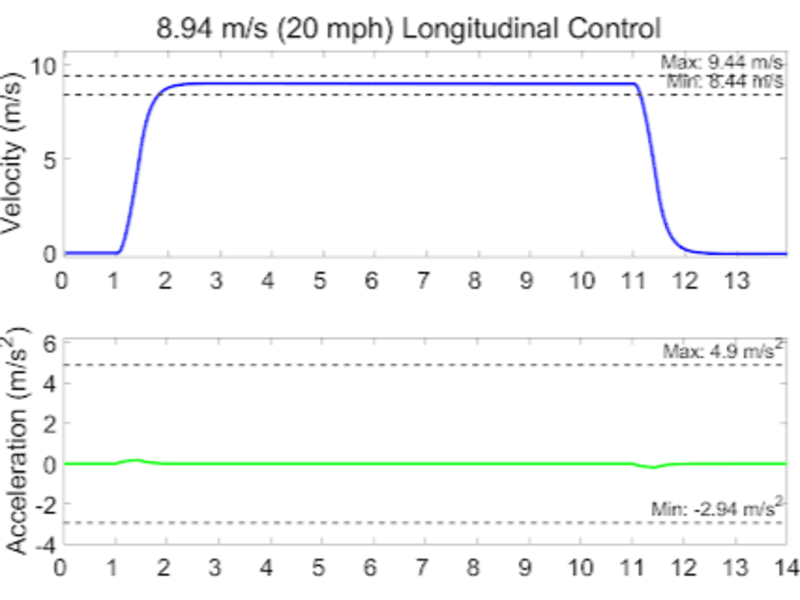

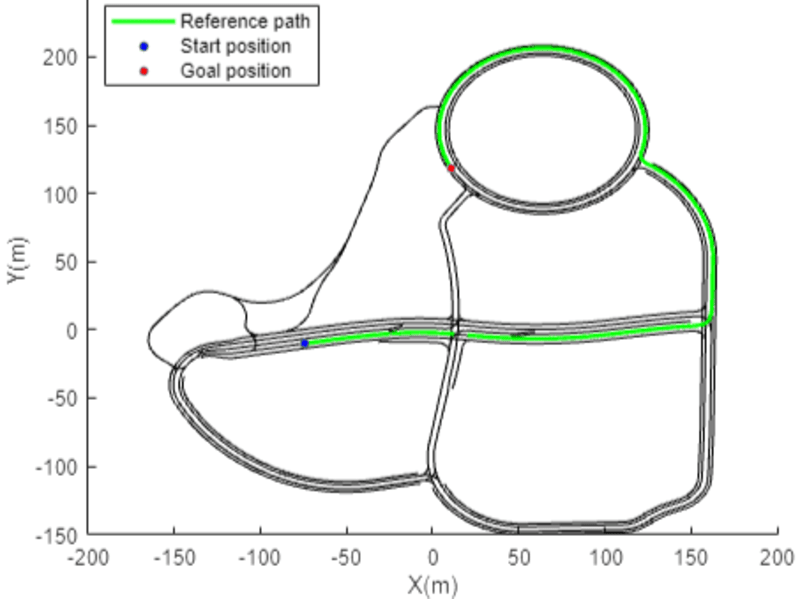

My experiences have involved combining software and hardware components, defining appropriate

simulation requirements and coordinating the design, development, and deployment of integrated systems.

I have demonstrated leadership within projects and work,

with additional experience in project management.

This website provides an overview of the various work experiences, projects, and other related activities

that I have been a part of since the start of my bachelor's degree.